CFD: GLYCOL CONTACTOR SCRUBBER - SINGLE PHASE

Condensate carryover from the scrubber section of the Glycol Contactor was causing foaming of the glycol and consequently poor contactor drying performance. Internals comprised a Half Open Pipe inlet device and a vane mist eliminator below the chimney tray.

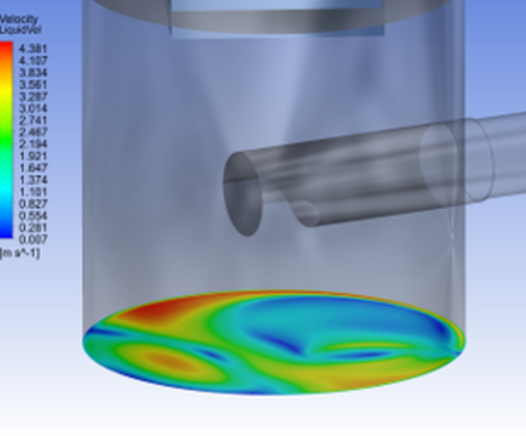

The root cause of the problem was found to be high gas velocities on the liquid surface that would cause gross re-entrainment of liquid. The re-entrainment was to such a degree that it was difficult to maintain a liquid level with the low incoming liquid rate.

Liquid re-entrainment from the liquid level can have a noticeable negative impact on the performance of separation vessels and is commonly overlooked. For instance it can lead to increased liquid loading to the vessel mist elimination devices that then increases liquid carryover to downstream equipment. As was the case here it can lead to an increased amount of hydrocarbon finding its way to the Glycol Regeneration system. For this phenomena use is made of the Kelvin Helmholtz relationship. This is described in the following equation:

Ug,cr = Critical Gas Velocity (m/s)

ρl = Liquid density (kg/m³)

ρg = Liquid density (kg/m³)

σ = Interfacial surface tension (N/m)

g = Gravitational Acceleration (9.81 m/s²)

If the actual gas velocity on the liquid surface exceeds the Critical Gas Velocity by a factor of 3 to 4 then noticeable re-entrainment is a possibility. For this case the calculation of this is provided below:

The solution was found in a complete reconfiguration of the internals. A vane type inlet device was fitted along with a mesh coalescer and axial flow cyclones. The latter two devices were fitted to enable a higher flow through the contactor.